💭 Reinventing food: The coming disruption

This is the greatest change to food production since domestication

Hi,

This is an analysis paying members of Exponential View received earlier this week.

In three weeks time, on the fifth anniversary of my starting to write this newsletter, EV will experience a small reinvention. I wanted to share a preview of the kind of expert insight members enjoy.

This analysis was based on a live briefing call for premium members we hosted with researchers at RethinkX, Catherine Tubb and Hannah Tucker. Hannah and Catherine presented their research on new technologies shaping food and agriculture. The briefing was hosted by EV’s Senior Advisor, Diana Fox Carney, who looks after our work on climate change and sustainability. Her notes are below.

I hope you enjoy it, and consider joining as a premium member at a special price (valid until the end of February)!

Members can also:

Watch the recording of the briefing with Hannah and Catherine,

View the slides,

Comment to continue the conversation,

RSVP to join our next briefing on the innovation behind low-carbon steel.

Diana’s notes on the briefing follow below.

Full technological disruption—which is the focus of RethinkX’s work—implies systems change, rather than simple product substitution. The classic example of this is the advent of the internal combustion engine. The US switched over from a system centred on animals to one based on motor vehicles in just twenty years, notwithstanding the resistance of the incumbents and an almost complete lack of infrastructure.

Hannah and Catherine described the process of disruption they see gathering pace in the food and agriculture system. Explaining technological disruption as a convergence of technologies that come together to unlock new possibilities, they argued that apparent shifts in the food system—such as the current “meat-free mania”—are driven by new technologies far more than by a consumer spiritual awakening or a health and environmental push on the part of governments. Initially, feedback loops hold back the new in favour of the old. Once certain tipping points have been reached, however, such loops begin to favour the new over the old. We then see the familiar ‘S curve’ of rapid adoption.

Software-led food design

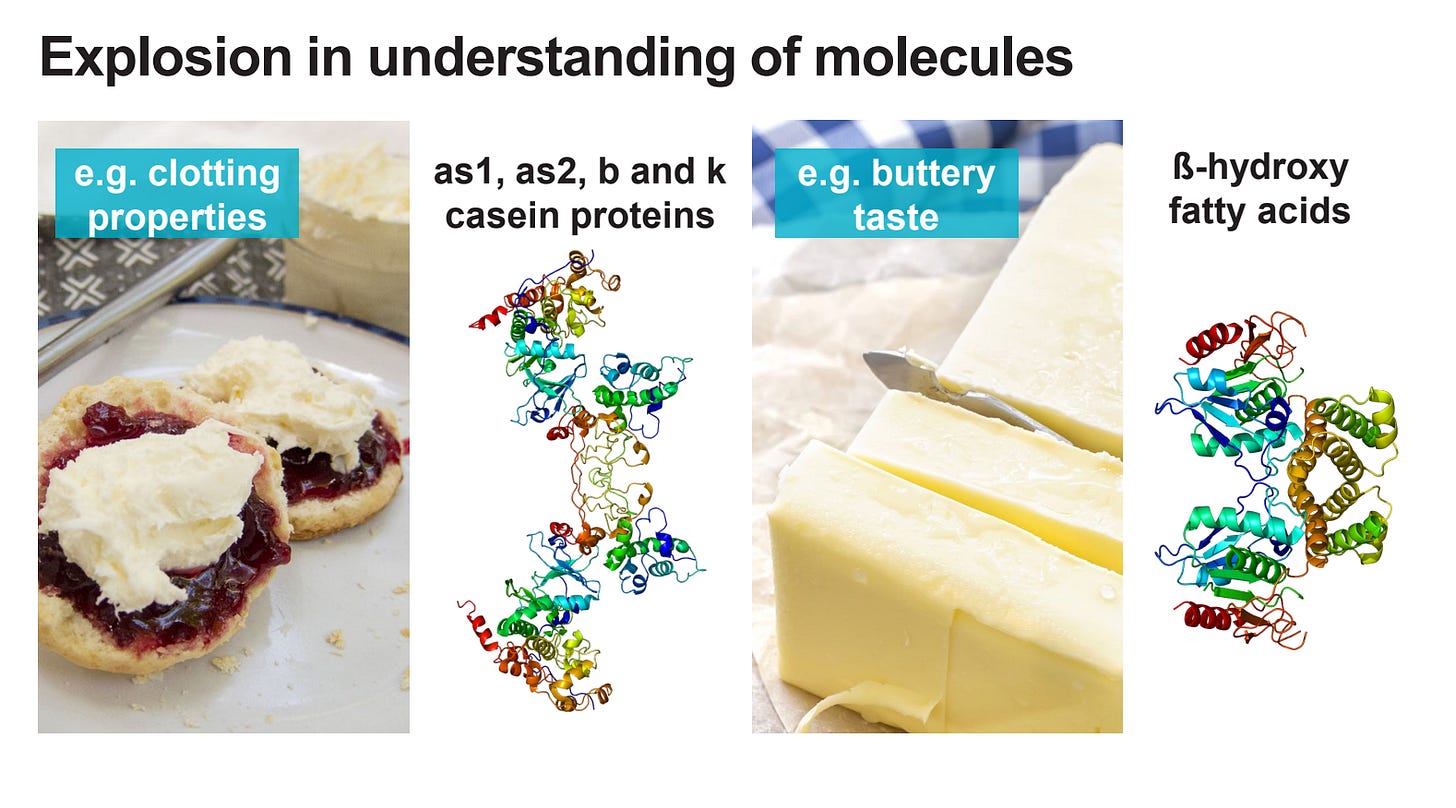

Food disruption is driven by the convergence of massively increased performance and reduced cost in the areas of advanced computing (e.g. processing power, data storage), and synthetic biology (e.g. genome sequencing and editing). Our understanding of protein molecules has exploded, and we now have precision control over cells. This means that we can harness them as mini molecular factories to directly produce any molecule we desire, allowing us to bypass the inefficient production systems we have lived with for so long (livestock).

We can design food from the molecule up—rather than breaking down and reconstituting bulk food products as we currently do in food processing (often through the use of heat and chemicals which can significantly reduce the nutritional quality of food). The technology also allows for mass iteration of products (the Impossible Burger is only in its second iteration—expect many more improvements over time) and for tailoring products to specific markets and end-users. We can rapidly iterate those designs for constant improvement, as well as customisation. Milk, for example, is 90 per cent water. If we can understand and recreate the 10 per cent of what makes milk special, we will be able to readily replicate or mimic milk without the need for cows. And that is just version 1.0, with mass iterations possible—and already underway— from there. This is software-led food design.

Software-led food design means that we can harness precision biology and bring it together with the age-old practice of fermentation, in a process called precision fermentation (PF). PF allows us to harness microbes (e.g. yeast, bacteria) as mini molecular factories to produce any molecule at high speed and volume. We select a micro-organism and programme it to produce our desired output (usually a protein) using plant-based inputs (any biomatter can be used though the efficiency of the system will be determined, in part, by the proportion of carbohydrates in the inputs). The resulting protein can then be mixed with other ingredients to create a suitable end product, using a fraction of the resources of the conventional alternative and, thus, at a fraction of the cost.

The first application of PF was in medicine in the 1980s to produce human insulin at large scale through modified yeast and fermentation. In just fifteen years, this cheaper, better form of insulin disrupted insulin in use from bovine and swine pancreas allowing us to go from a very limited to an effectively unlimited supply of insulin. Since then, the cost of PF has continued to decline at an exponential rate. Today, PF costs about $100/kg and is cost competitive on a like for like basis with for certain cosmetics, high-value materials, and specialty foods. By 2025, they expect PF-produced proteins to cost $10/kg and therefore be cost competitive with mass market, bulk foods.

Where to next?

What is in front of us is a new, modern protein system. Cow meat is the first area of disruption, but there are already chicken products available and the disruption will affect most proteins (eggs, pork, salmon, prawns, etc.). There are also groups working on palm oil, sweeteners, coffee: we can produce any molecule in this way, it is just a question of what makes sense from a cost perspective.

The next iteration of this process is likely to be with lab-grown meat. PF will decrease the cost of the media used in the process and will add the proteins that act as the scaffold for the meat (so as to create the texture and cuts that consumers want).

We should also expect to see not just the replication of familiar food items, but also the advent of entirely different types of food enabled by our understanding of molecules and the new processes. If we are lucky enough that food disruption goes hand-in-hand with health disruption, enabling a dramatically better understanding of how different foods interact with our bodies, we could end up producing quite different foods with significantly improved health consequences.

What are the implications of this disruption?

Catherine and Hannah argue that the cow is facing an existential crisis.

They suggested that we will move rapidly away from cow protein, so that by 2030, 70 per cent of the lab-produced proteins consumed in the US will come from modern methods (i.e. software-designed foods with a combination of plant, PF and cultured proteins), resulting in 50 per cent reduction in the need for cows in the US by 2030. By 2035, industrial cattle in the US (i.e. cattle within the industrial food system) could become obsolete. While these figures and the broader analysis focused on the US, this disruption is unfolding globally at a similar speed and scale.

Producing food in this way makes massively better use of resources and allows us to effectively overcome scarcity. The process is cheaper (potential 10x improvement in efficiency as compared to livestock), less volatile and risk-prone, and can be widely dispersed and decentralised.

Changes in the food system will obviously affect the structure of the industry. Given how competitive it is, just small changes in prices will have a large impact. Already, two US dairy processors have gone bankrupt.

Incumbents in the industry have already become engaged with PF. For those that trade in ingredients for processed foods, engaging with these new options is clearly an imperative. Expect “business-to-business ingredient-led disruption.” For those upstream in the industrial animal agriculture industry, whether in feedlot operations or slaughterhouses, it is a greater threat and they can be expected to resist and push back (cow-based dairy industry fighting over product naming, for example).

The new system will be decentralised which will mean that there will be savings on transport costs, too. At present, the cost barriers to entry are quite high, but we are already seeing these falling, and new, smaller fermentation systems coming to market which may be operated under licencing agreements (there has also been repurposing of hardware originally developed for the bio-ethanol revolution). Less well-off nations should also be able to become involved: already we see interest and research in this area in both China and India. Asked about the impact on smaller farmers, especially in developing countries, Hannah and Catherine suggested that (a) they could continue to produce premium products for specific markets and (b) they could be paid for the environmental services they provide depending on the equilibrium levels at which costs and revenue stabilises in the new market. The bleeding edge of disruption will definitely take place at the industrial end of the farming spectrum.

One of the big questions is around the nutritional quality of the new proteins. At present, the incentives of the food system are such that nutrition is well-down on the list of factors that influence whether food is brought to market (after taste, texture, convenience, cost). We could design for nutrition, but whether we will, remains an open question. We must, though, take into account that plant protein is not necessarily nutritionally equivalent to animal protein. We made that mistake with fats, moving rapidly away from saturated animal fats, rich in Omega-3, to polyunsaturated, highly processed vegetable fats, with appreciable adverse population health consequences.

How will this affect the climate and the environment?

One of the key concerns, environmentally, is whether our current food system can actually feed the world’s growing population. It is likely that with the effects of the current level of climate change on crops, and overall food production (including fish) we may not be able to do this sustainably. This is before we even take into account the growing demand for animal proteins from richer developing nations. PF gives us an alternative: an entirely new system that could meet today’s challenges without compromising our environment.

Overall, for each protein produced from PF as opposed to the cow we will require:

10-25x less feedstock

5x less energy

10x less water

100x less land.

At present 40 per cent of US land is dedicated to cows; in the move to the modern protein system, they estimate we will need just one fifth of this 40 per cent (so 8 per cent overall) going forward.

Potential positive environmental benefits from this shift are:

Less methane produced by livestock

Less water required

Less energy / fewer inputs required (for the carbon-intensive production of fertilisers, for example, for the crops that feed the livestock)

Land released from both grazing and feedstock production for reforestation and regeneration, with scope for better soil carbon sequestration

Reduced transport emissions

Lower food spoilage rates as fewer bacteria in the system

Overall, the estimates suggest that the new systems, with land freed up for carbon sinks, could actually be carbon negative overall.

At present, PF systems use quite a lot of energy (30 per cent of costs), but this will change as renewable energy becomes more available.

What will affect the adoption trajectory?

Adoption of these new technologies will be affected by many factors, including consumer decisions (will the new foods be acceptable, either as ingredients—easier— or as stand-alone products?), business and investment decisions, and regulation (including around how the allocation of intellectual property affects the development of the industry, ranging from an open-source, distributed system to a closed model like the pharmaceutical industry, with a few big players). Once we get into entirely new classes of foods, food safety regulation could provide a break on progress (or accelerate it).

Depending on how these factors play out, we could end up with slower adoption and lower penetration, though they still expect cost and other benefits to drive huge change (so we might reach 60 per cent rather than 90 per cent adoption of animal protein substitutes). There is no reason that these foods cannot prosper alongside more traditional products and ways of producing them, that are valued for other reasons.

Dig deeper:

Rethinking Food and Agriculture, RethinkX, 2019

Disrupting dairy with precision fermentation: ‘By 2035, industrial cattle farming will be obsolete, Food Navigator, 2020

Taking Over Staple Status: Modern Meat and Potatoes, Disruption Dinner, 2020